Description

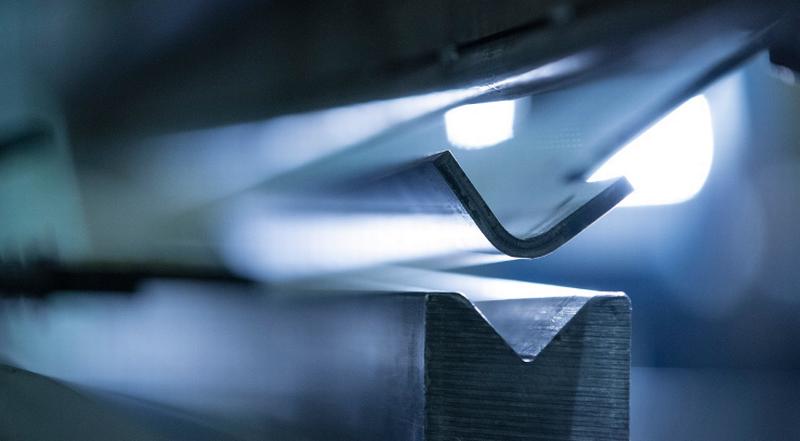

Coremark Metals houses eight press brakes, each with varied and unique capabilities, plus the greatest selection of tooling in the Midwest. This allows us to handle your complex shapes and designs with ease and convenience. Our experienced operators use quick connect tooling which translates to less set up time, major cost savings, and faster lead times for our customers.

Need assistance with your project? Request a free quote and turn your concept into reality today.

Capabilities

ALLOYS

ALUMINUM:

2024, 3003, 5005, 5052, 5086

BRASS & COPPER:

260 Brass, 110 Copper

STAINLESS STEEL:

304/304L, 316/316L, 409, 420, 430

STEEL:

A36 (Hot Rolled and Pickled & Oiled), GR50, 1018 Cold Rolled, A588/A606, Galvanized

MACHINES

6' - 60 Ton

12' - 175 Ton

12' - 235 Ton

12' - 250 Ton

16' - 600 Ton

THICKNESS & TOLERANCE

THICKNESS:

26ga - 1.000"

STANDARD TOLERANCE:

+/- 0.063"

ADDITIONAL TOLERANCE:

>+/- 0.125"

+/- 0.030"

NOTCHING

ALUMINUM:

0.024" to 1/4" thick material

STAINLESS STEEL:

24ga to 11ga thick material

STEEL:

24ga to 3/16" thick material

Quote Request

A mark against which to be measured, our products and services are centered on reliability, expert advising, convenience, and empowering creation…we’re all about making it work for you. Click here to connect with our experienced engineers and make your custom project a reality.

Request a QuoteDrawing & Files

Required File Formats:

DWG, DXF, IGS, IPT, PDF, or STEP

In-house drawing capabilities available for an additional drafting fee.